A short guide to how glass is made

Methods of making glass have changed considerably over the centuries, from a highly skilled craft to today’s high volume industrial production. One of the most important innovations in the glass industry was the development of the Float Glass production process and we’d like to give you an insight into how float glass is made today.

From skilled craftsmen to industrialization

Glass was first discovered around 5,000 BC. For centuries, individual craftmanship dominated and it was not until the 20th Century that glass production became industrialized and mass produced in sheets. But there was still one major drawback: glass had to be ground and polished on both sides to obtain the desired quality – a process that was very time-consuming and costly.

Then came perhaps the greatest innovation in glass history – the introduction of the Float Glass production process, popularized in the 1960s. This breakthrough led to a dramatic rise in the use of glass around the world.

Float glass is the foundation of Guardian’s offerings today, from coated solar control glass, to laminated safety, anti-reflective and mirror glass.

The float glass process

The process of making float glass is rather like preparing and cooking a carefully planned meal. You start by collecting all the required ingredients, then follow a specific set of processes that include heating to the correct temperature then cooling in the right manner. Follow the recipe to the letter and the results are worth the effort.

What is glass made of?

Primarily, soda-lime-silica glass is made up of three main components: sand, soda ash, and limestone. Float glass also contains dolomite, used to improve the hardness and chemical resistance of float glass.

A short history of glass

The oldest known glass objects, such as beads, date back to around 2,000 BC. For centuries, glassmaking relied on the skilled craftsmanship of individuals, and glass remained a luxurious material, typically used for jewelry or decorative items. It wasn’t until the 19th century that glass became commonplace in homes and public buildings. Although float glass technology was first patented in the early 20th century, it was significantly advanced and brought to market in the 1950s by Pilkington Brothers Limited. By the mid-1960s, their version of the float process began to replace traditional glass manufacturing methods, offering improved surface quality and reduced production costs.

Pilkington’s innovative float glass method is now the most widely used technique for making flat glass.

How is float glass made?

Float glass is made by dissolving raw materials in a furnace (a process commonly named melting) and then pouring the mix continuously onto a bath of molten tin. Gravity and surface tension allow it to float on the surface and transform into a flat, smooth sheet known as a ribbon. After the melting and shaping processes, the ribbon is cooled and cut to size.

The typical width of the ribbon is 3.21 meters (or 126 inches) in Europe, and either 3.30 meters (130 inches) or 3.66 meters (144 inches) in North America. Standard float production dimensions can vary slightly depending upon the region. The ribbon thickness can range from approximately 2 to 19 mm, or 3/32” to 3/4”.

Float glass lines can be up to 500 meters (1,600 feet) in length and are kept in continuous operation. Typically, a float glass line will have a lifespan of about 18 to 20 years. A medium-sized float glass line can produce 600 tons of glass per day.

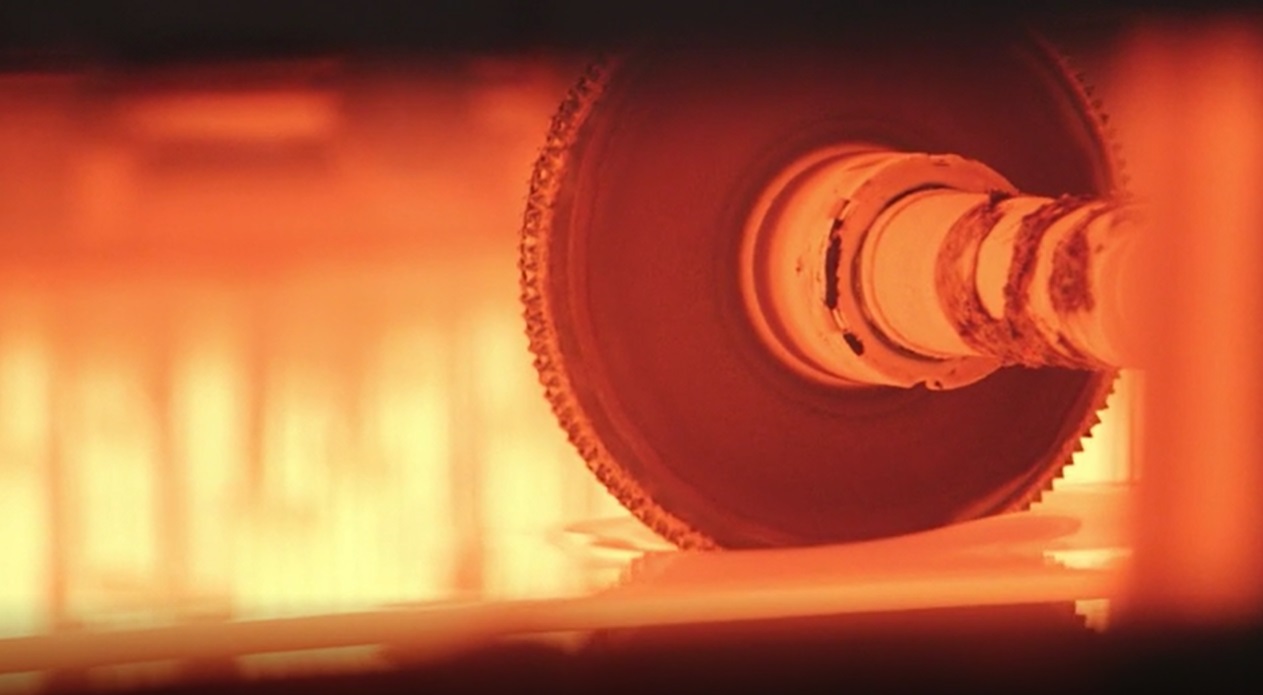

See in this video how float glass is made:

What are the raw materials used in float glass manufacturing?

The raw materials used in the float glass process are a mixture of silica sand, soda ash, limestone, and dolomite. By weight, float glass contains approximately 70-75% silica sand, 15% soda ash, and 15% of a combination of limestone and dolomite. Float glass also contains small amounts of salt cake, carbon, and iron oxide.

Each component plays a critical role. Silica sand creates a rigid, glassy structure. Soda ash lowers the melting temperature of silica and makes the glass malleable and easier to dissolve. Limestone acts as a stabilizer and improves the durability and hardness of the glass. Dolomite enhances the glass’s viscosity control and its resistance to chemicals.

How the melting process works

Once each raw material has been accurately weighed according to the required recipe, it is thoroughly mixed in the batch house before being transferred to the furnace hopper. 15% to 25% of the batch mixture for standard float glass is made up of crushed glass known as cullet. Cullet is usually sourced from previous production batches, but can be supplied by specialized recycling companies or glass processors. Cullet must be rigorously inspected to ensure it meets quality standards.

Tools known as chargers are used to insert the mixture into the furnace. A float glass line furnace has a melting zone of approximately 1,500 to 1,600 °C (2,700 to 2,900 °F).

In a regenerative furnace, a series of natural gas side burners maintains the temperature. Each set of burners operates in turn for approximately 20 minutes before switching to the other side. The exhaust gas from the furnace is fed through the opposite inactive regenerator, maintaining the regenerator temperature, and conserving significant amounts of energy.

How glass is shaped

After the melting process, the molten glass ribbon is fed into a conditioning basin via a flow-restricting waist mechanism. The molten glass is stirred by water-cooled paddles before entering the tin bath. Before being floated atop the molten tin, the glass passes through a movable barrier called a tweel. Molten tin has low reactivity with glass and high density, higher than molten glass. These properties allow glass to float smoothly on its surface, resulting in perfectly flat sheets.

The thickness of the glass normalizes at approximately 6 mm. Different thicknesses can be achieved by operating top rollers, known as knurls, that stretch the glass as the line speed is increased to produce thinner glass. To produce thicker glass, the top rollers compress the glass, and the line speed is reduced.

At the end of the shaping process, the temperature of the glass will drop from approximately 1,100 °C (2,000 °F) to approximately 600 °C (1,100 °F). The glass leaves the tin bath in an almost solid state.

The importance of cooling glass

The glass then passes into an annealing lehr to cool. This is a temperature-controlled area used to gradually cool the freshly formed glass. The annealing lehr is made up of a closed channel followed by an open stretch exposed to forced air. Annealing lehrs are quite long and usually run for approximately 200 meters (700 feet).

During the annealing process, forced air lowers the temperature of the glass to an ambient level. As the glass cools, internal stresses are removed, and the glass takes on a uniform stress profile. The uniformity of the stress profile enables the glass to be cut into industrial stock sheets and stored.

What are the properties of glass?

Modern architectural glass goes far beyond transparency. Float glass is a precisely engineered material with well-defined strength, durability and optical clarity.

These properties enable glass to be used for a wide variety of applications. Heat-treatening, coating and laminating the glass enhance the properties of the glass and add functionality such as increased strength, solar control, thermal insulation, safety, security, acoustic performance, and more.

Quality control in glass manufacturing

Maintaining quality is crucial in glass manufacturing. Laser sensors or high-resolution cameras are used to detect defects. These areas are cut out of the glass sheets and used as cullet.

Environmental performance in glass production

We are dedicated to improving the environmental performance of our manufacturing processes and products across their entire lifecycle. This includes using fewer natural resources, minimizing waste, and continually innovating to operate efficiently and responsibly.

A standout example is our furnace in Bascharage, Luxembourg, which features next-generation technology and stands as our most energy-efficient furnace to date.

Another example is Guardian NEXA™, a range of lower carbon glass solutions (up to 38% reduction in embodied carbon*), achieved by optimizing manufacturing processes and raw materials selection.

How glass is made FAQs

What are the stages of glass manufacturing

Gathering raw materials, melting, shaping, cooling, and cutting.

What is glass made of?

Sand, soda ash, limestone, and dolomite. Other substances can also be added to enhance the glass.

What is float glass?

Float glass is made by pouring molten raw materials onto a bed of molten tin. This results in perfectly even, flat glass sheets that do not require grinding or polishing.

Making laminated glass

While float glass provides an excellent base product, laminating the glass can add other benefits such as color, sound control, safety and security. This helps make the glass more suitable for today’s demanding architectural applications, whether the end-use is sound reduction, hurricane impact-resistance, anti-intrusion, protection from broken glass – or a combination of these.

Laminated glass consists of glass sheets bonded together using a plastic interlayer. The glass and interlayers can be supplied in a variety of colors and thicknesses to provide the desired appearance and performance to suit your application.

While laminated glass can still break, the fragments tend to stick to the plastic interlayer and remain largely intact, reducing the risk of injury. As such, laminated glass can qualify as safety glazing.